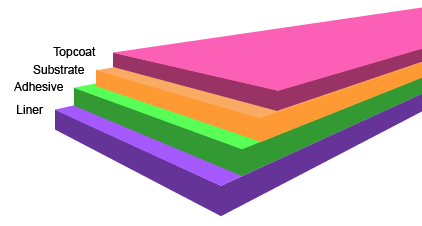

Substrate Components

Liner

The liner is almost always a paper material with a silicon coating. Its primary function is to promote easy handling of the label from pre-print to print and protect the adhesive layer. The liner is removed at the end of the printing process when the label is ready to adhere to its intended object.

Adhesive

This layer forms a bond between the printed substrate material and the object to which it will adhere. There are many types of adhesive, each designed to meet specific application requirements. When determining what type of adhesive is required, there are many things to consider. For example:

- Does the label need to be permanently affixed to a surface or easily removed?

- Is the surface to which it will be applied rough or smooth?

- Will the label be used in any extreme environments such as high temperature or high humidity?

Substrate

Substrate layers for thermal transfer printing are made of paper or one of many different types of synthetic material, depending on the desired durability of the application. The substrate is the actual material that carries the printed image.

Topcoat

The topcoat layer is almost always present for thermal transfer receptive labels. This layer encourages adhesion of the various thermal transfer inks to the substrate layer.