Printer Mechanics

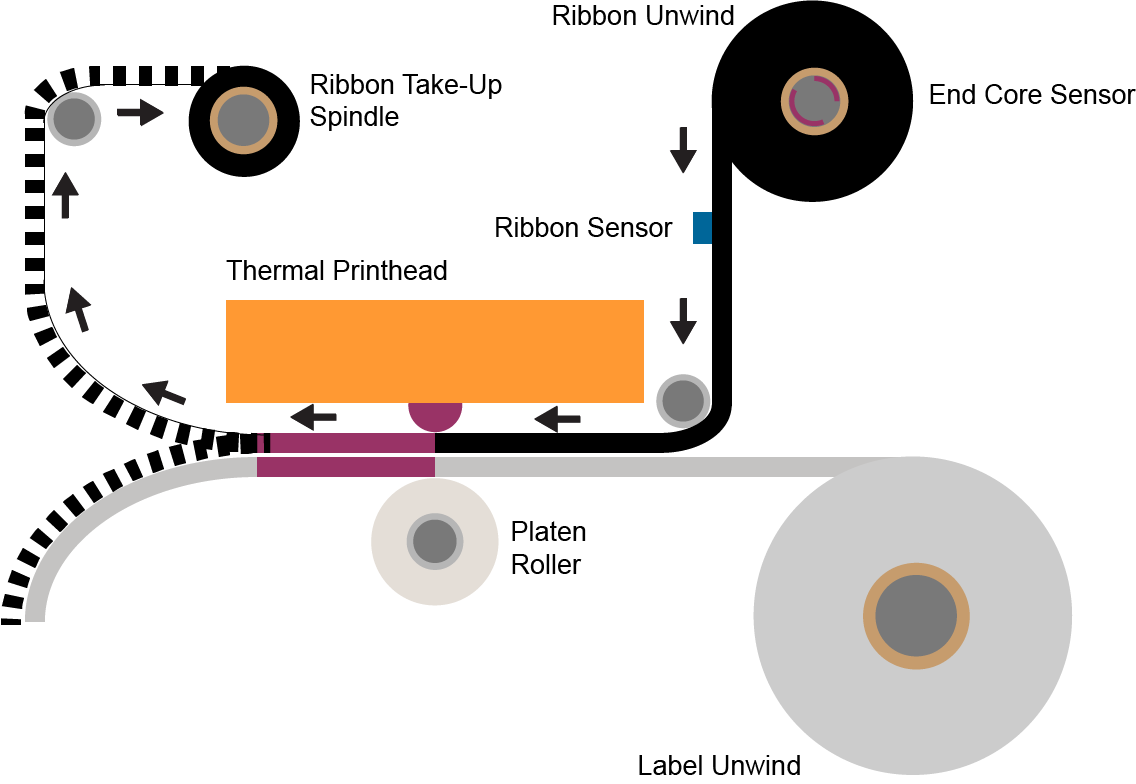

Ribbon Unwind

The ribbon unwind serves one primary function—hold the TTR roll in place while the thermal printer is running. TTRs are wrapped around cores (see TTR Components) that fit perfectly onto the ribbon unwind. Usually the ribbon unwind is located in front of the label unwind and both are pulled under the thermal printhead by the movement of the platen roller.

Label Unwind

The label unwind holds the roll of labels in place while the thermal printer is printing. The labels are placed on the label unwind and fed between the platen roller and printhead, along with the TTR. As the thermal printing process continues, the labels are pushed out of the printer by the force from the platen roller.

Ribbon Take-Up Spindle

After the TTR has been pulled through the platen roller and thermal printhead, it must be manually attached to the ribbon take-up spindle. The ribbon take-up spindle rotates in the opposite direction of the ribbon unwind to collect the TTR after it has passed through the thermal printing process. The ribbon take-up spindle allows for easy disposal of the used TTR.

Ribbon Sensor

The ribbon sensor is an important component of the thermal transfer printer. It senses if a TTR is in place. This sensor also detects the end of a TTR roll by notifying the printer's internal computer when it has reached the trailer film. Not all thermal transfer printers use a ribbon sensor—some thermal printers use an end core sensor. Both sensors have similar functions—to detect the end of a TTR roll. Detecting the end of a TTR roll before it reaches the thermal printhead is important for protecting the thermal printhead.

End Core Sensor

The end core sensor is located inside the ribbon unwind. Its primary function is to detect a lack of motion from the ribbon unwind. This process works closely with the TTR's end film and adhesion to the core. The end film of a TTR is loosely attached to the core. When the TTR reaches the end of its roll, the constant rotating motion will detach the end film from the core and the ribbon unwind will cease its rotations. The end core sensor will detect this lack of motion and notify the thermal printer's internal computer to stop printing.

Thermal Printhead

The thermal printhead is the most important mechanism of a thermal transfer printer. The thermal printhead consists of a fixed number of heating elements corresponding to the thermal printhead's printing resolution. Once fired, these heating elements transfer heat through the TTR and onto the label substrate. When combined with pressure, this completes the printing process by transferring the melted ink to the label substrate.

Platen Roller

The platen roller is usually a stationary roller centered directly under the thermal printhead and serves as a multi-functional component in the thermal printing process. A small motor spins the platen roller into motion. This motion guides the TTR and label through the thermal printer and, more importantly, under the thermal printhead for printing. The platen roller is also used to help feed the TTR and label into the thermal printer.