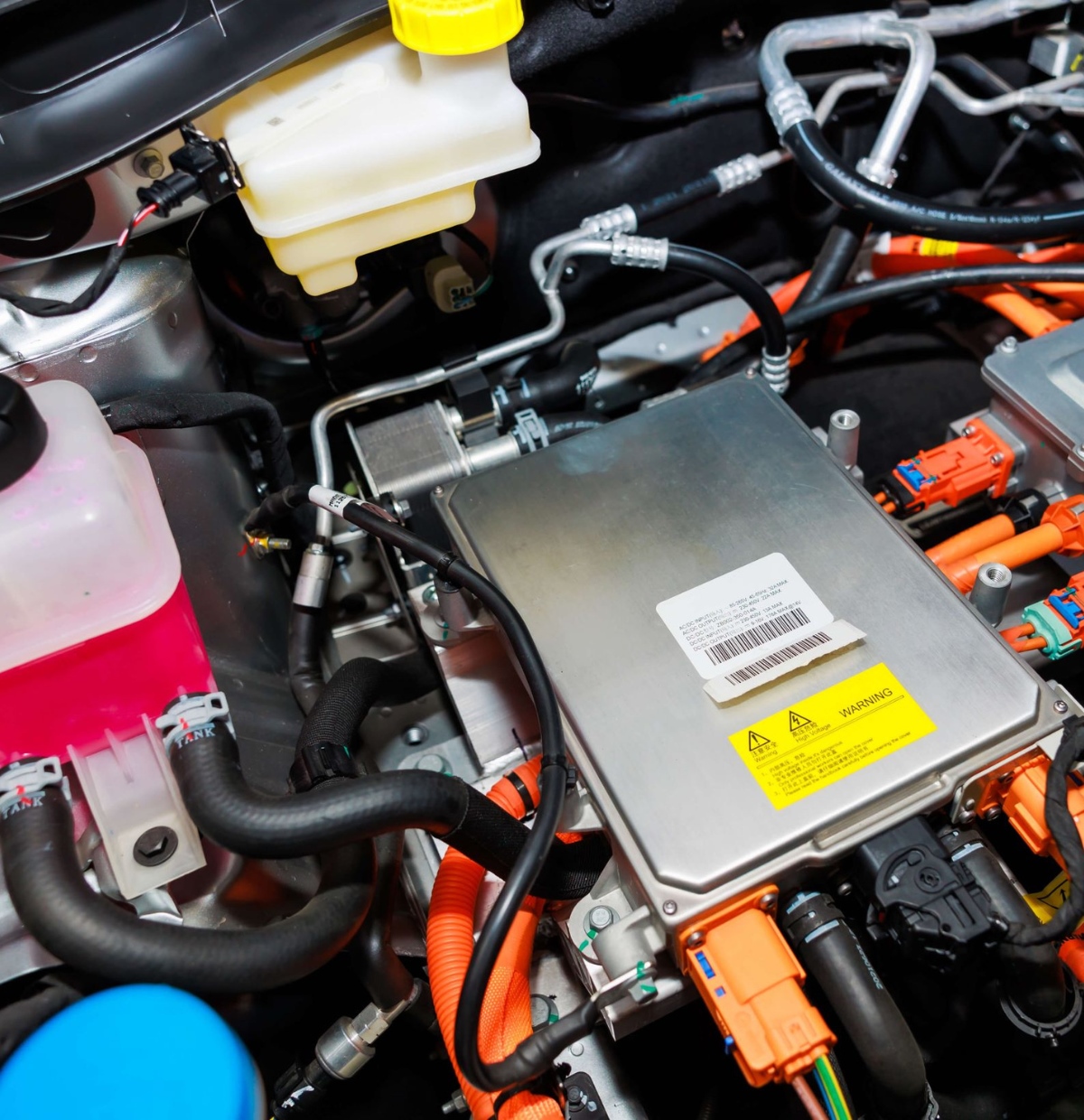

Recently, we had a customer who makes safety harness equipment having issues with safety tags losing their marking after time in the field. Due to the dangerous settings this equipment is used in, the harnesses are essentially unusable in the field without the proper safety information being legible. The customer was using a synthetic material to create the labels with a wax/resin combo ribbon. After calling DNP for suggestions, they recommended trying an R300 full resin ribbon. We were able to take a ribbon from stock to their manufacturing facility for testing and solved the problem. Thanks to DNP, we were able to help our customer keep their customer, and there is no way to put on number on that kind of value.

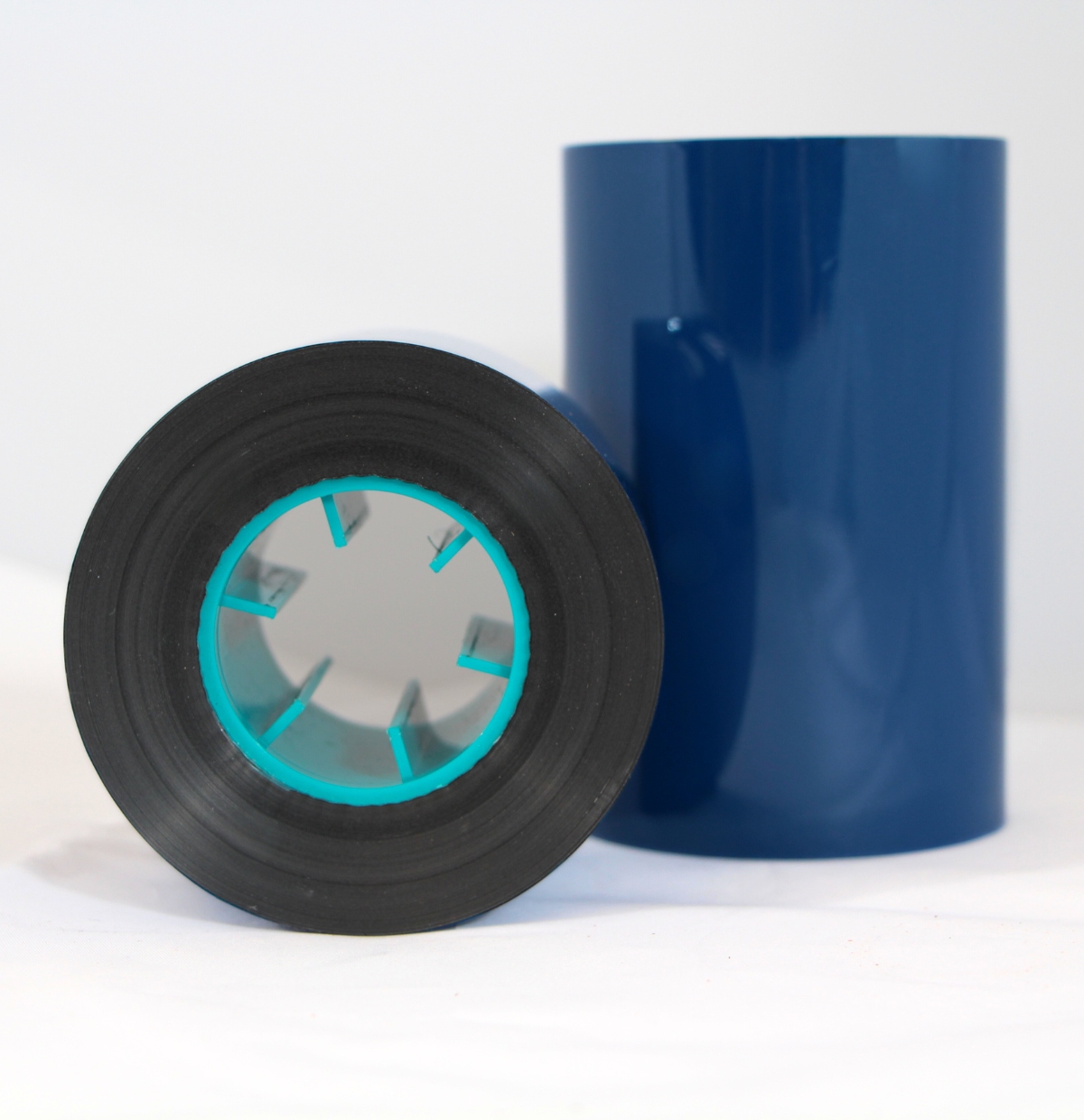

R300

General Purpose Resin

- Scratch and Smudge Resistant: Provides strong protection against scratching and smudging, ensuring clean, sharp images and text that last.

- Solvent Resistance: Formulated to withstand exposure to various chemicals, enhancing durability.

- Exceptional Edge Definition: Produces crisp, clear edges for high-quality prints.

- Polyesters (Gloss Topcoat)

- Polyesters (Matte Topcoat)

- Polyethylene

- Polyimide

- Polyolefin

- Polypropylene

- Polystyrene

- PVC Shrink Wrap

- Vinyl (Topcoat)

- BS5609

- FDA Indirect Food Contact

- REACH Compliant

- RoHS Compliant

- UL

| Base Film Thickness | 4.5 ± 0.4 μ |

| Ink Thickness | 1.3 ± 0.4 μ |

| Total Thickness | 5.8 ± 0.8 μ |

| Transfer Temperature | 390°F / 199°C |

Industries & Applications

Stories That Inspire

At DNP, we work hard to give our customers the best possible experience. It makes us proud when customers are ready to share that story.

Frequently Asked Questions

Have questions about our thermal transfer ribbons or services? Explore answers to common inquiries, and if you need more help, our team is always here for you.

Under normal operating conditions, thermal transfer ribbons do not break. However, a label design with a large, concentrated area of ink can weaken the ribbon, leading to breakage. Keep this in mind when designing your label format.

Begin by setting both the speed and heat to half of your printer’s maximum range.

- If the print is too light – slowly increase the heat/decrease the speed.

- If the print is too dark – decrease the heat/increase the speed.

The only difference is the length of the ribbon, as the film and manufacturing processes are identical. Sample rolls are between 50 and 100 meters, while full-size rolls meet the OEM specification for length.

All grades (wax, mid-range, and resin) contain both wax and resin components. The type of wax or resin determines a ribbon's performance characteristics rather than the ratio of each. DNP uses the highest quality ingredients to ensure precise melt points and premium performance.

The ink transfer temperature is not the temperature required to transfer ink to a label during printing, as commonly believed. Rather, it is the temperature at which a printed image will smudge. DNP provides the ink transfer temperature for each formulation on technical datasheets.

DNP thermal transfer ribbons are produced, manufactured, and processed in the United States. To ensure we offer a comprehensive product portfolio, specialty formulations are coated at our headquarters in Japan and imported to our Mount Pleasant, Pennsylvania facility for finishing.

DNP manufactures ribbons according to the printer OEM specifications for width and length. Ribbons outside their tolerances may be challenging to load or unload or cause problems during printing. DNP recommends following the OEM specifications and selecting a ribbon width equal to or slightly larger than the label.

Smearing or smudging typically signals a compatibility issue between the ink and the label material. While printer adjustments rarely resolve the problem, testing to identify the ideal ribbon and label combination often does. DNP's Application Lab can help! It's equipped with the industry's leading printers and a comprehensive inventory of label materials. Our experts are ready to recommend the perfect ribbon solution for your needs.

The Versatility Series features four advanced thermal transfer ribbon formulations designed to address over 90% of common industry applications. Each ribbon delivers consistent, reliable, and high-quality results while offering proven compatibility with a wide range of substrates and material variations.

MP Mid is now V200 Versatile Wax-Resin! With strong market adoption and a proven track record, MP Mid has earned its place in the Versatility Series. Known for its reliable performance on a wide range of synthetics and papers, V200 continues to set the standard for versatile thermal transfer printing.

We're Here to Help!

Do you have a question about a product or need technical assistance? We're here to help! DNP's knowledgeable customer service team is ready to support you at every step.

Simply fill out our customer inquiry form or contact us using one of the methods listed below. We’re committed to helping you get the most out of your DNP experience. Reach out today—your success is our priority!

Simply fill out our customer inquiry form or contact us using one of the methods listed below. We’re committed to helping you get the most out of your DNP experience. Reach out today—your success is our priority!