About Us

We make the world's premier thermal transfer ribbon, right here in America.

At DNP, we don't make thermal transfer ribbon, we craft it – with dedication, experience, the finest materials and stringent quality control. It's in our DNA. Because over twenty-five years ago, DNP was one of the first companies to pioneer thermal transfer ribbon technology, and we've never stopped. If you think, "Blue leader, black ribbon, what's the difference?" The difference is DNP.

We're part of DNP Imagingcomm America Corporation.

DNP Imagingcomm America Corporation is a U.S.-based subsidiary of Dai Nippon Printing Co., Ltd. Since starting our U.S. operations in 1995, our division has grown to be the world’s largest manufacturer of thermal transfer ribbons for barcode and dye-sublimation printers. DNP is also the world’s largest diversified printing/coating technologies company. At its 59 plants, both in Japan and overseas, DNP’s operations include commercial printing, packaging, decorative materials, electronics, business forms and information media supplies. DNP is a global corporation with $15 billion in annual revenue.

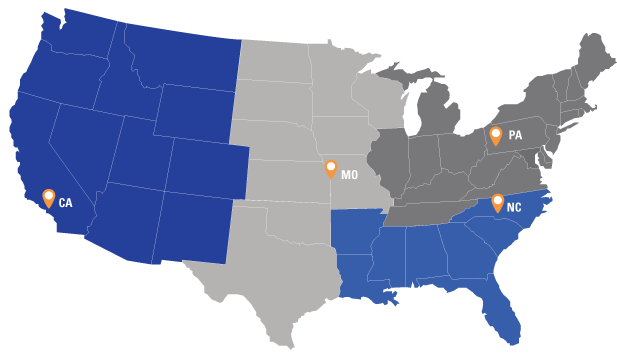

Four distribution centers serve you coast to coast.

We know you and your customers want to get products quickly. That's why we have four distribution centers located strategically throughout the United States. Our distribution network provides industry-leading transit times on our most popular items. And we do all the work – choosing the best center to get your shipment to its destination using the fastest route – to save you time and money. And there's no extra cost for this service. It's one of many valuable perks that comes from being a valued partner.

We have one of the most comprehensive R&D networks in the world.

DNP invests in six independent laboratories to support our various divisions, creating an unrivaled network of Research and Design. Our development process starts at our Central Research Institute (CRI), where scientists study new or emerging industries and technologies. Once the CRI team establishes a new business opportunity, they transfer the project to our Manufacturing Technology Integration Laboratory (MTI). There, DNP's top engineers, chemists and physicists work together to design the most efficient and technologically advanced method to build and manufacture the new product. This approach to research and development enables DNP to operate at maximum efficiency – a savings we can continually pass on to our customers. It also ensures that our products and processes consistently set the industry standard for quality and reliability.

We are committed to sustainable growth.

DNP is actively working to preserve the environment. Corporately, we strive to achieve zero emissions, reduce water usage, protect biodiversity, thoroughly control use of VOS and other chemicals, develop eco-friendly products, and pursue green purchasing.

Today in Mount Pleasant, Pennsylvania:

- We are operating below our energy consumption target.

- We recover and reuse 80% of the solvent needed to manufacture our TTR.

- DNP thermal transfer ribbons are wound on cores made from 55% recycled material.

- Our formulations are RoHS-compliant and free of heavy metals.

- We carry a full line of halogen-free products.

- Over half by weight of what is transferred from our V4085plus formulation is all-natural.

- Our product packaging is made of 45% recycled material.

Additionally, used DNP ribbons are being recycled and converted into alternative fuel. See Recycling Thermal Transfer Ribbons to learn more.

Our ISO-certified operations are highly effective and efficient.

DNP is committed to highly effective and efficient operations through ISO-certified management system standards. We hold both ISO 9001 and ISO 14001 certification.

ISO 9001 is one of the most widely used management tools in the world. Certified organizations must demonstrate a Business Management System capable of providing a product and/or service that meets customer and regulatory mandates.

ISO 14001 is a framework for an environmental management system that companies can follow and become certified. This is a voluntary standard that helps to reduce waste, conform to applicable laws and regulations, and improve company image.

See our International Organization for Standardization (ISO) page to learn more and download our certificates.